ARTU PROFI-LINE

Diamond drills

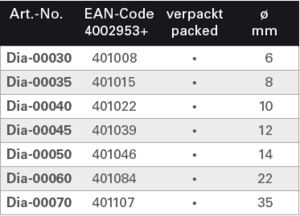

Diamond drills with quick hex shank (6-18 mm)

ARTU diamond drills have a sintered segment consisting of metal powder and diamond particles, which is pressed together before being sintered (“baked” at high temperature). The sintered segment is then silver-soldered to the steel body of the drill. Ideal for drilling porcelain, stoneware, marble, granite and other very hard stone.

For best results, use a power drill at full speed (2,500-3,000 RPM). Cordless drills may also be used, of course, but the drilling operation will take longer because cordless drills are slower than conventional power drills.

The segment must be cooled! It is usually sufficient to simply dip the drill in water and then drill for 4-5 seconds. Repeat the process after drilling for 4-5 seconds, although experience shows that the drill only needs to be dipped 2-3 times to complete the job (8 mm thick porcelain stoneware). If cooling is insufficient, the outer diamond layer “burns off” and the drill must be “reactivated” (conventional diamond drills would be damaged beyond repair) with plenty of water. This exposes the next diamond layer and the drill can be used again in the normal way.

The service life of ARTU diamond drills is up to 10 times longer than that of conventional (electro-plated) drills currently on sale. In addition, our diamond drills are also ideally suitable for glass, where a drill speed of 2,500-3,000 RPM also applies. More frequent dipping is necessary, so it is better to drill glass under running water, in a water bath or with the help of a wet sponge (press the sponge against the workpiece while drilling).

Drill sizes have been determined to ensure that there will be no problems with inserting plugs, for example. The hole drilled must be slightly larger than the nominal plug size e.g. our nominal size 6mm is actually 6.2 mm.

No “stirring” is required when using ARTU drills. ARTU drills allow you to drill straight into the material as you would with conventional HSS or masonry drills.

If you do not wish to use the drill guide supplied, you will first have to drill a “furrow” at an angle of 45° (to prevent the drill from slipping) and then slowly increase the angle to 90°.

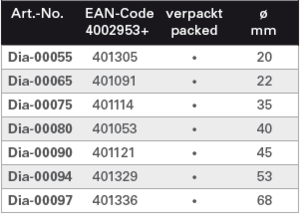

Diamond crowns 20-68 mm dry

ARTU diamond crowns from size 20 mm upwards have an M14 socket for angle grinders. The technology is the same as that of the smaller diameters (sintered segment). What is special about ARTU crowns is that we use only a single segment!

This enables you to drill more even holes without damaging the tile. There are sintered diamond crowns with 4 or 6 segments on the market; if you drill porcelain stoneware with one of these, you will hear a loud “rattle” as the segments strike the tile (there are gaps between the segments). Our crowns are for dry drilling. No waxing, no stirring required!

Diamond hole saw with watercooling

Sintered single segment. Hexagonal “Quick Change” socket. Extremely long service life (lasts for 50 or more holes in the hardest 8mm thick tiles). Ideal for use on porcelain tiles/porcelain stoneware, marble, granite and glass. Drills must be cooled; it is usually sufficient to simply dip in water before drilling for 3-5 seconds (2 dipping operations are usually enough for a 10mm thick tile). The drill can be “reactivated” in the event of a “burnout”. The only one of its kind on the market! Simple drilling into a grindstone or other abrasive material (approx. 3 holes with water) will expose the next diamond layer and the drill is as good as new. For best results, use a power drill at 2,500-3,000 RPM (about 10 seconds at highest drill speed for an 8mm thick porcelain tile), but good results can also be obtained with a cordless drill.

Diamond hole saw dry drilling

ARTU diamond crowns from size 20 mm upwards have an M14 socket for angle grinders. The technology is the same as that of the smaller diameters (sintered segment). What is special about ARTU crowns is that we use only a single segment!

This enables you to drill more even holes without damaging the tile. There are sintered diamond crowns with 4 or 6 segments on the market; if you drill porcelain stoneware with one of these, you will hear a loud “rattle” as the segments strike the tile (there are gaps between the segments). Our crowns are for dry drilling. No waxing, no stirring required!

Diamond drill set 4-piece

in plastic case

watercooling

1 x 6mm / 1 x 8mm / 1 x 10mm / 1 x 12mm

![]()